Results from Operation

1 Overview

From the very beginning of the test stage, it became clear that the crusher was unable to break intact glass bottles. On the wide setting, which was specifically implemented for this purpose, the crusher did manage to pull in the bottles, but the exerted force was not high enough to crush them. The crank arm jammed up each time, and even though it felt physically possible to push it further, the drivetrain was suspected to get damaged before the bottle would. A sturdier drivetrain and an even larger gear ratio would certainly help mitigate the problem; however, there are limits to the availability of motorcycle sprocket sizes and to the clearance within the crusher’s drivetrain. Since a 2-layer compound gear train would be counterproductive for the sturdiness issues, a solution would likely require a fundamental redesign of the drivetrain. Therefore, the crusher was instead considered to be a fixed system, restricted to the narrowest setting only. This decision was facilitated by the fact that the process of adjusting the roller gap turned out rather cumbersome anyway.

2 Glass crushing results

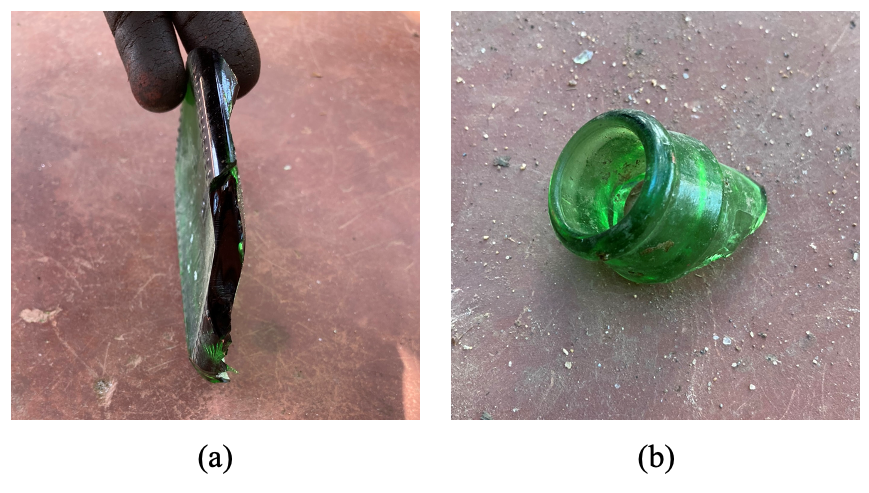

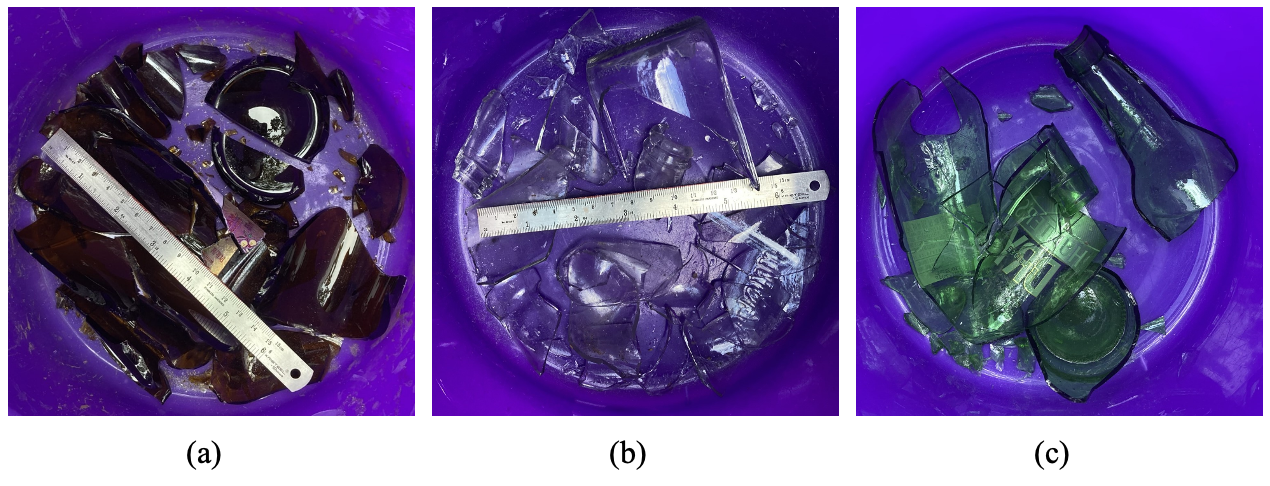

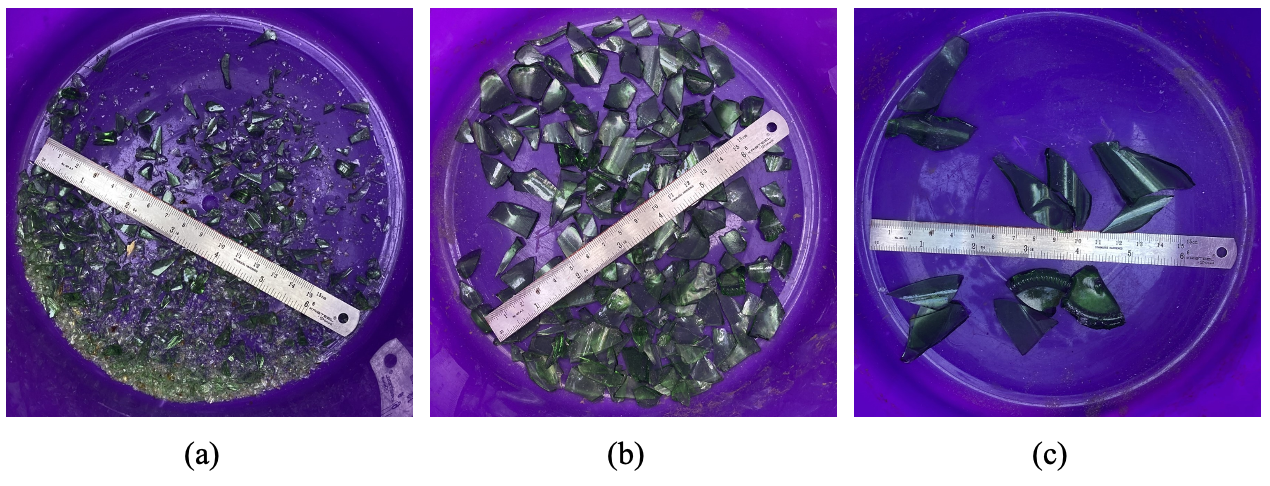

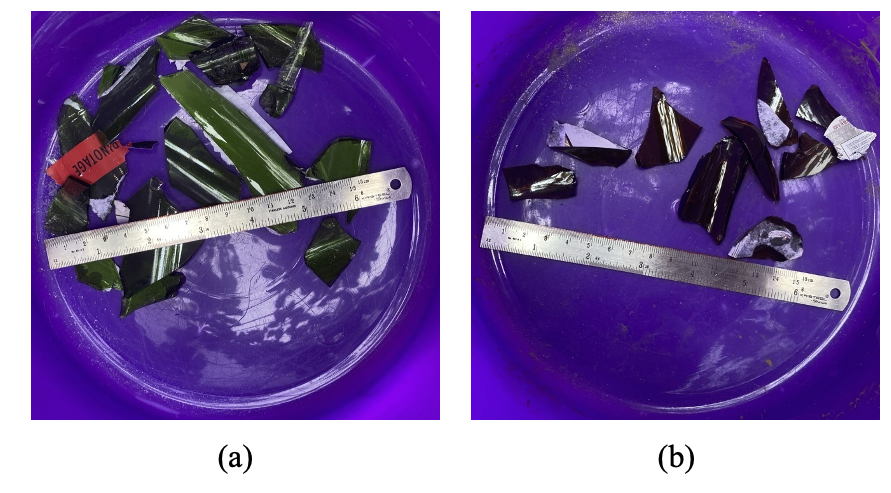

For testing the bottles were broken using a hammer before loading into the crusher. Figure 1 shows some examples for the state the glass was in before being inserted into the crusher. Figure 2 shows an example for the result after sorting; it more specifically depicts the shards produced form the batch in Figure 1 (c). The shards produced by the crusher were sorted into three categories: Small for shards smaller than 1 cm, medium for shards between 1 cm and 3 cm, and large for shards larger than 3 cm.

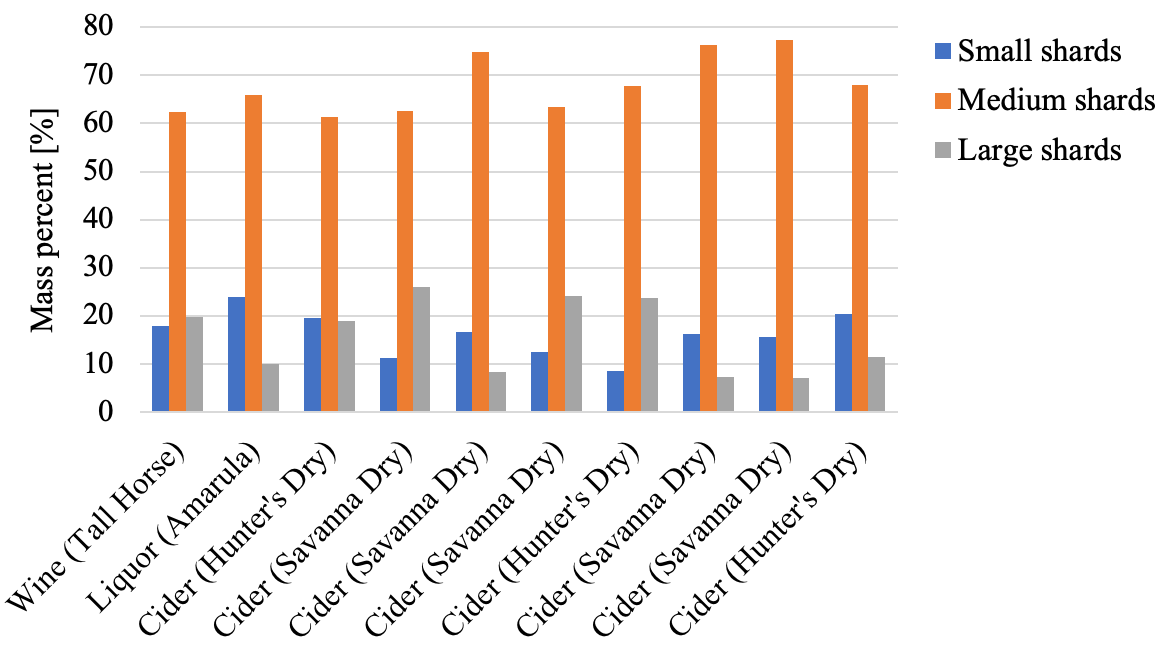

As can be observed in Figure 3, there is some variation in the shard composition of the different batches, but overall, the medium category is always by far the predominant one, making up for 61 % to 77 % of the mass. There seems to be no clear trend regarding the percentages of small shards relative to the large ones, ranging from equal proportions to ratios slightly below 1:2 and vice versa. In short, with its single setting, the crusher is able to produce a variety of particle sizes ranging from powder to shards several centimeters long, but if one is only interested in a specific size, they have to be sieved first.

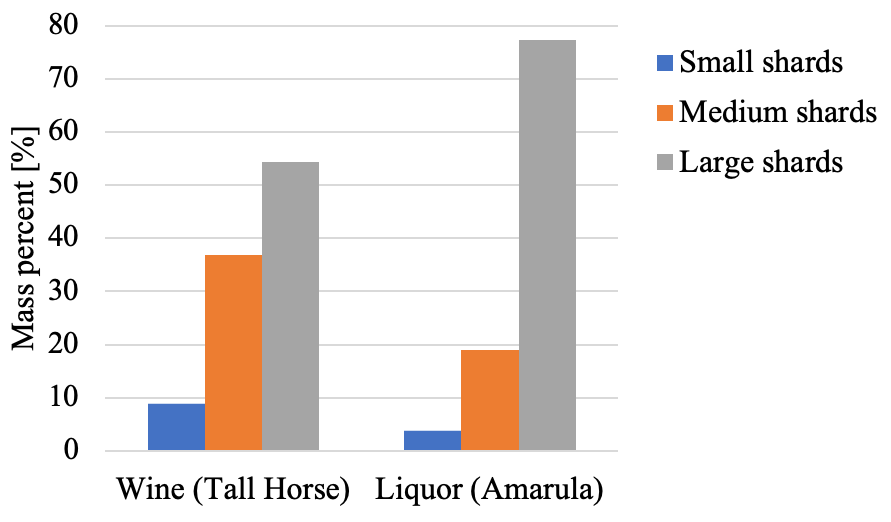

To determine whether it makes sense to process the batches a second time to obtain a larger quantity of smaller shards, the large shards of the wine and liquor bottle were given a second pass through the crusher. Almost half of the wine bottle’s shards classified as small or medium afterwards, compared to only a quarter of the liquor bottle’s shards (Figure 4). Taking into account that the wine bottle’s shards were larger to begin with (Figure 5), thus decreasing their probability of getting through the crusher unscathed, this result is little surprising. In conclusion, repeated passes have diminishing benefits and are only worth the effort if the shards are still excessively large.

On two occasions during testing, the crusher jammed when it encountered a particularly rigid piece of glass. The first time it was caused by the circa 9 mm thick base of a Jägermeister bottle during one of the crusher’s preliminary tests (Figure 6 (a)), the second time by the neck of a cider bottle (Figure 6 (b)). After removing them, the crushing process was resumed without issues.